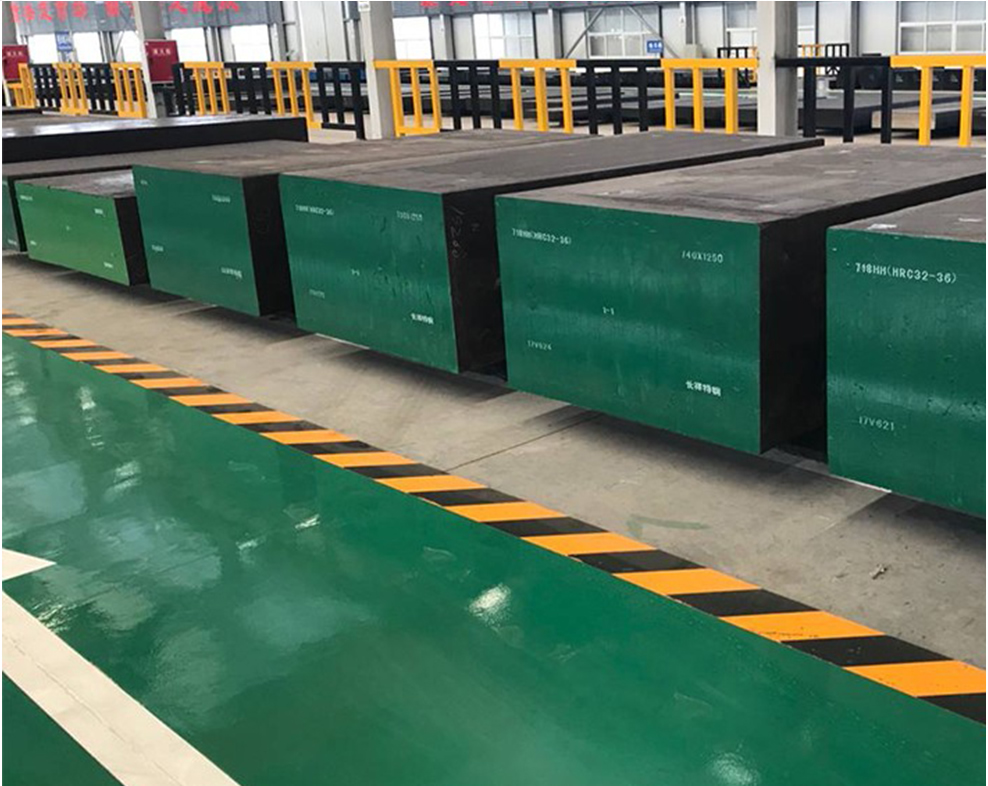

1. Transparent plastic mould

2. Highly stressed cutting and punching tools for thin sheets

3. Stone processing tools and knives for paper and plastics,shear knives

4. Requiring higher food industrial equipment parts and PVC / PP / EP

1. Stampo di plastica trasparente

2. Strumenti di taglio e punzonatura altamente sollecitati per fogli sottili

3. Utensili per la lavorazione della pietra e coltelli per carta e plastica, coltelli da taglio

4. Richiedere pezzi di attrezzature industriali alimentari pi¨´ alti e PVC / PP / EP

Contact ANHUAI CO., LTD for more information about the 1.2083 | S136 | 420steel.

Contatta ANHUAI CO., LTD per ulteriori informazioni sull'acciaio 1.2083 | S136 | 420.

1. Equivalent grades/Gradi equivalenti

| Germany(DIN) | Japan(JIS) | USA(AISI) | Sweden(SS) | China(GB) |

| 1.2083 | SUS420J2 | 420 | S136 | 4Cr13 |

2. Chemical Composition(%)/Composizione chimica(%)

| Steel Grade | Chemical Composition(%) | |||||

| C | Si | Mn | P | S | Cr | |

| 1.2083 | 0.36-0.42 | ¡Ü1.00 | ¡Ü1.00 | ¡Ü0.030 | ¡Ü0.030 | 12.50-13.50 |

| SUS420J2 | 0.26-0.35 | ¡Ü1.00 | ¡Ü1.00 | ¡Ü0.035 | ¡Ü0.030 | 12.00-14.00 |

| 420 | 0.26-0.40 | ¡Ü1.00 | ¡Ü1.00 | ¡Ü0.040 | ¡Ü0.030 | 12.00-14.00 |

| S136 | 0.38 | 0.9 | 0.5 | ¡Ü0.040 | ¡Ü0.030 | 13.6 |

| 4Cr13 | 0.36-0.45 | ¡Ü0.60 | ¡Ü0.80 | ¡Ü0.035 | ¡Ü0.030 | 12.00-14.00 |

3.Heat Treatment/Trattamento termico

Annealing : 810 - 830 ¡ãC

Hardness after annealing : Max230 HB

Stress relieving : Approx. 650 ¡ãC

Hot forming : 1050 - 850 ¡ãC

Hardening: 970 - 990 ¡ãC

Quenching media : Oil, Vacuum

Hardness after quenching : 30-36 HRC

Ricottura: 810 - 830 ¡ã C

Durezza dopo la ricottura: Max230 HB

Distensione: ca. 650 ¡ã C

Formatura a caldo: 1050 - 850 ¡ã C

Indurimento: 970 - 990 ¡ã C

Mezzi di estinzione: olio, vuoto

Durezza dopo tempra: 30-36 HRC