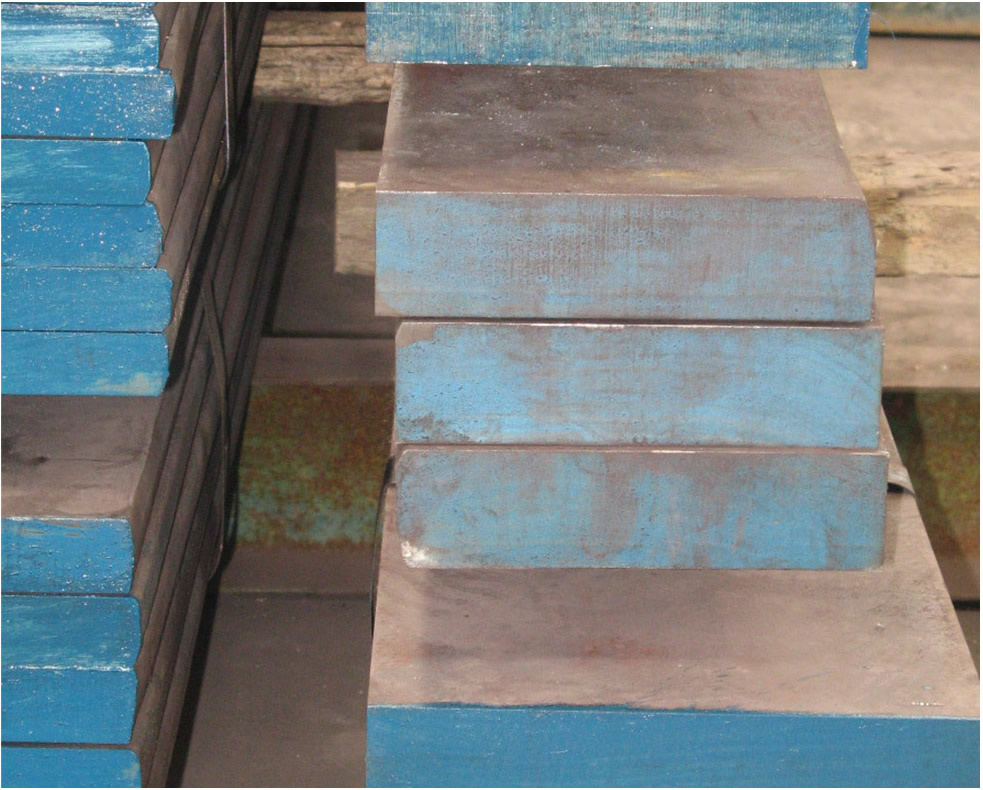

O1 steels are mainly used for short run tooling for cold forming dies, blanking dies, and cutting tools operating at ambient temperature.

Typical applications for O1 tool steel are blanking, forming, and trim dies, gages, slitting cutters, punches, bolster dies, knock-out pins, thread roll dies, bending dies, plastic mold dies, shims, cams, machine ways, stamps, machine parts, jigs, cutter templates, swaging dies, etc.

Gli acciai O1 sono principalmente utilizzati per utensili a breve durata per stampi a freddo, stampi per tranciatura e utensili da taglio funzionanti a temperatura ambiente.

Le applicazioni tipiche per l'acciaio per utensili O1 sono tranciatura, formatura e stampi di intestatura, calibri, taglierine, punzoni, matrici di sostegno, perni a percussione, matrici per rullatura, matrici di piegatura, matrici di plastica, spessori, camme, macchine, timbri, parti di macchine, maschere, maschere di taglio, matrici di stampaggio, ecc.

ANHUAI CO., LTD info@xingxionggroup.com for more information about the O1|1.2510|SKS3|100MnCrW4 steel.

ANHUAI CO., LTD info@xingxionggroup.comper ulteriori informazioni sull'acciaio O1|1.2510|SKS3|100MnCrW4.

1.Relevant Steel Specifications of O1|1.2510|SKS3|100MnCrW4 Tool Steel / Specifiche di O1 | 1.2510 | SKS3 | 100MnCrW4

2. O1|1.2510|SKS3|100MnCrW4 Tool Steel Chemical Composition & Equivalents/ O1 | 1.2510 | SKS3 | 100MnCrW4 Acciaio per utensili Composizione chimica ed equivalenti

3. O1 | 1.2510 | SKS3 | 100MnCrW4 Tool Steel Mechanical Properties /Propriet¨¤ meccaniche per O1 | 1.2510 | SKS3 | 100MnCrW4

Physical Properties/Propriet¨¤ fisiche

Thermal Properties/Propriet¨¤ termiche

Country

USA

German

Japan

Standard

ASTM A681

DIN EN ISO 4957

JIS G4404

Grades

O1

1.2510/100MnCrW4

SKS3

ASTM A681

C

Mn

P

S

Si

Cr

V

W

Mo

O1

0.85

1.00

1.00

1.40

0.03

0.03

0.10

0.50

0.40

0.70

. . .

0.30

0.40

0.60

. . .

. . .

DIN ISO 4957

C

Mn

P

S

Si

Cr

V

W

Mo

1.2510

0.90

1.05

1.00

1.20

0.03

0.03

0.15

0.35

0.50

0.70

0.05

0.15

0.50

0.70

. . .

. . .

JIS G4404

C

Mn

P

S

Si

Cr

V

W

Mo

SKS3

0.90

1.00

0.90

1.20

0.03

0.03

0.35

0.50

1.00

. . .

. . .

0.50

1.00

. . .

. . .

Properties

Metric

Imperial

Hardness, Brinell (soft annealed -delivery condition)

190

190

Hardness, Rockwell C (tempering temp 300-1200¡ãF)

34.0-64.0

34.0-64.0

Elastic modulus (hardened to 62 HRC)

193 GPa

28000 ksi

Elastic modulus (@399¡ãC/750¡ãF, hardened to 62 HRC )

172 GPa

25000 ksi

Elastic modulus (@191¡ãC/375¡ãF, hardened to 62 HRC)

186 GPa

27000 ksi

Compressive yield strength (0.2%, hardened to 50 HRC)

1350 MPa

196000 psi

Compressive yield strength (0.2%, hardened to 55 HRC)

1800 MPa

261000 psi

Compressive yield strength (0.2%, hardened to 60 HRC)

2150 MPa

312000 psi

Compressive yield strength (0.2%, hardened to 62 HRC)

2200 MPa

319000 psi

Properties

Metric

Imperial

Density (hardened to 62 HRC)

7.81 g/cm3

0.282 lb/in3

Density (@399¡ãC/ 750¡ãF, hardened to 62 HRC)

7.70 g/cm3

0.278 lb/in3

Density (@191¡ãC/ 375¡ãF, hardened to 62 HRC)

7.75 g/cm3

0.280 lb/in3

Melting point

1421¡ãC

2590¡ãF

Properties

Conditions

T (¡ãC)

Treatment

Thermal expansion

10.6 x 10-6/ºC

20-260

¨C